|

|

|

|

|

| NATTY is a specially processed hi-tech product, using quality Portland cement, calcium silicate, diatomaceous earth and non-organic fiber through high temperature steam incubation under the guidance of the advanced Japanese technology. It is green and environment-friendly, a safe reliable construction material having fire-proof, wet-proof, moulds-proof, sound-proof, heat-proof, shock-proof, impact-proof features. Now the material is widely used for indoor partition, outdoor curtain, piping chamber, kitchen and restroom partition, underground clean room and ceilings. |

Thickness(mm) |

Width x Length (mm) |

Corner/edge Handling |

6 / 8 / 9 |

10 / 12 / 15 |

18 / 20 / 25 |

|

915 x 1830 |

1220 x 1830 |

1220 x 2440 |

|

Right Angle |

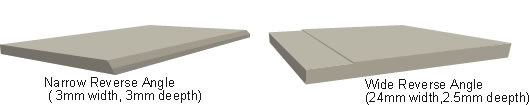

Reverse Angle |

|

|

|

1. Density: 1100~1450kg/m3

2. Bending strength:

Vertical-130 kgf/cm2 above

Horizontal-110 kgf/cm2 above

3. Impact-proof: Test sample was not penetrated by a

0.5 kg drop hammer impacted

4. Heat Conduction: 0.1 kcal/m.hroC below

5. Linear Expansion: below 0.1%

6. Conform to CNS6532 Incombustibility class 1

7. Fire-proof : 1hr fire-proof rating in drywall structure

8. Mould-proof, Germproof |

|

|

|

|

| 1. Light Steel Frame |

| a. |

Draw the installation line to define the fixing position. |

| b. |

Use the shooting steel nail to fix top C-STUD, and floor C-STUD on the ceiling and floor. |

| c. |

Arrange the vertical C-STUD according to the request (usually 400mm), and install the horizontal C-STUD. |

|

| 2. Fixing Method of NATTY board |

| a. |

To cut the board as per required size which is 10mm shorter than the wall high. |

| b. |

The boards should be in crisscross arrangement fixed on C-STUD by the tapping screw.

The Distance between tapping screw is 200~250mm, and each screw should enter 0.5mm depth into the board. |

| c. |

Please leave a joint about 3mm between boards. |

| d. |

When fixing the board, please fix from its center to edges. Don’t fix it at different points at the same time to avoid the over bending of the board. |

| e. |

Before fixing, we can place rock wool or glass fiber into the empty space between the boards to get better effects of sound-proof and fire-proof if necessary. |

|

|

|

|

Appellation |

(unit:m/m) |

L.(FT.) |

Stuff |

U-BAR |

38 x 12 x 1.0 |

12' |

EG |

W-BAR |

45 x 19 x 0.45 |

12' |

EG |

HANGING HOOK |

6 |

|

EG |

|

|

|

|

| 1. |

Draw the installation line to define the fixing position. The center distance is 1200mm. |

| 2. |

Use the hanging to link and fix the boom and main W-Bar, and keep main W-Bar in horizontal. |

| 3. |

Use the caliper to fix sub W-Bar vertically on main W-Bar. The center distance of sub W-Bar is 612mm. |

| 4. |

Use the tapping screw to fix the board on the sub W-Bar, and finish the joint connection. |

|

|

|

|